Need some advice? Give us a call.

Need some advice? Give us a call.

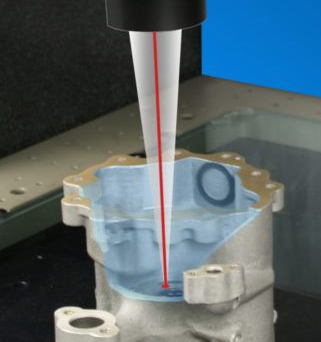

Single point touch trigger probing extends measurement versatility of measurement systems. Touch trigger probe, you can measure features that are difficult to image, or surface boundaries that are inaccessible to video. TP200 has higher accuracy and durability.

| TP20/TP200 | |

|---|---|

| Probe length [mm] | 10 - 100 |

| Change racks | 2 - 6 |

Access to small features that are inaccessible to video measurement or conventional touch probes. Using a specific sensing technology to determine when a resonating stylus has come close enough to a surface to dampen its resonance. This sensor can acquire a data point with only milligrams of force making it perfect for fragile components. Mounted on a motorized deployment mechanism.

| FP | |

|---|---|

| Probe length [mm] | 19,4 - 31,5 |

| Styli diameter [mm] | 0,1 - 1,6 |

SP25M Scanning Probe provides continuous contact scanning which offers high-speed data gathering. The scanning probe automatically adjusts point density when the probe is rounding curves. Change racks allow for different probes to be automatically exchanged.

| SP25 | |

|---|---|

| Probe length [mm] | 20 - 400 |

| Resolution [μm] | <0,1 |

| Measuring range [mm] | ± 0,5 in all directions |

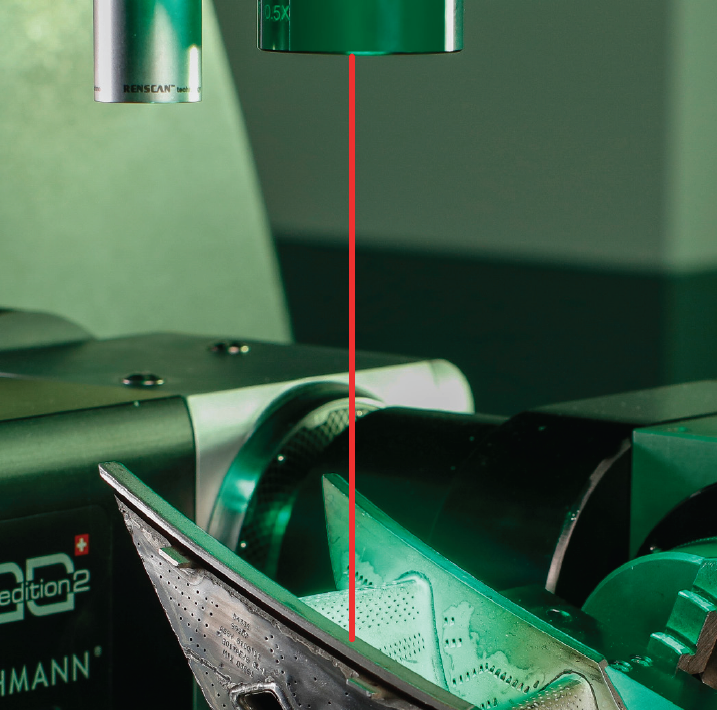

TTL Lasers offer a non-contact method for measuring surfaces. The long working distance scans surfaces without the risk of striking.. Dynamically adjusts the Z-axis to track part contours automatically.

| 2.0x (standard) | 5.0x (optional) | |

|---|---|---|

| Measuring range [μm] | 500 | 80 |

| Accuracy [μm] | 0,4 | 0,2 |

| Working distance [mm] | 38 | 19 |

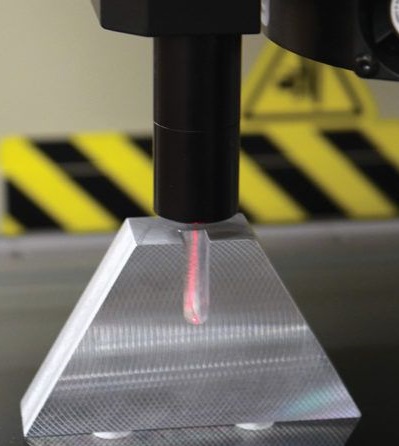

Provides non-contact, high-resolution surface contouring. Both linear and area scans are easily programmed into automatic measurement routines. Laser is mounted in mechanical deployment mechanisms.

| DRS 500, 500B | Red laser | Blue laser |

|---|---|---|

| Range [μm] | 500 | |

| Accuracy [μm] | 1 | |

| Working distance [mm] | 17 | |

| Ideal for | reflective surface | transparent or white parts |

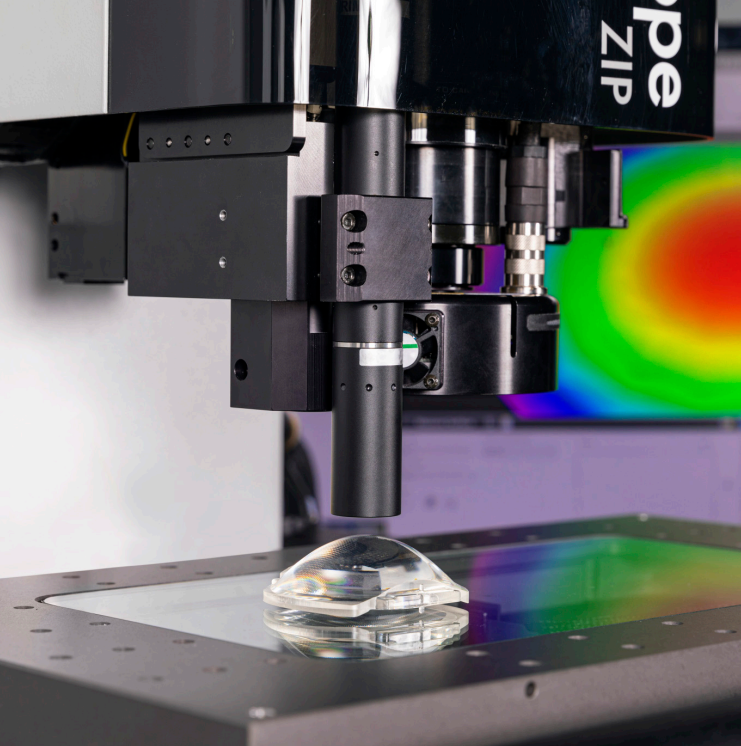

Analyzing changes in the optical spectrum as a function of part-to-probe spacing as it scans. Easily measures transparent, translucent, fragile, liquid, or easily deformable surfaces. Mounted in mechanical deployment mechanisms so it can be retracted when not in use.

| CL1 | CL2 | CL3 | |

|---|---|---|---|

| Measuring range [mm] | 0,15 | 0,4 | 1,4 |

| Accuracy [μm] | 0,02 | 0,06 | 0,2 |

| Working distance [mm] | 3,3 | 10,8 | 12,2 |

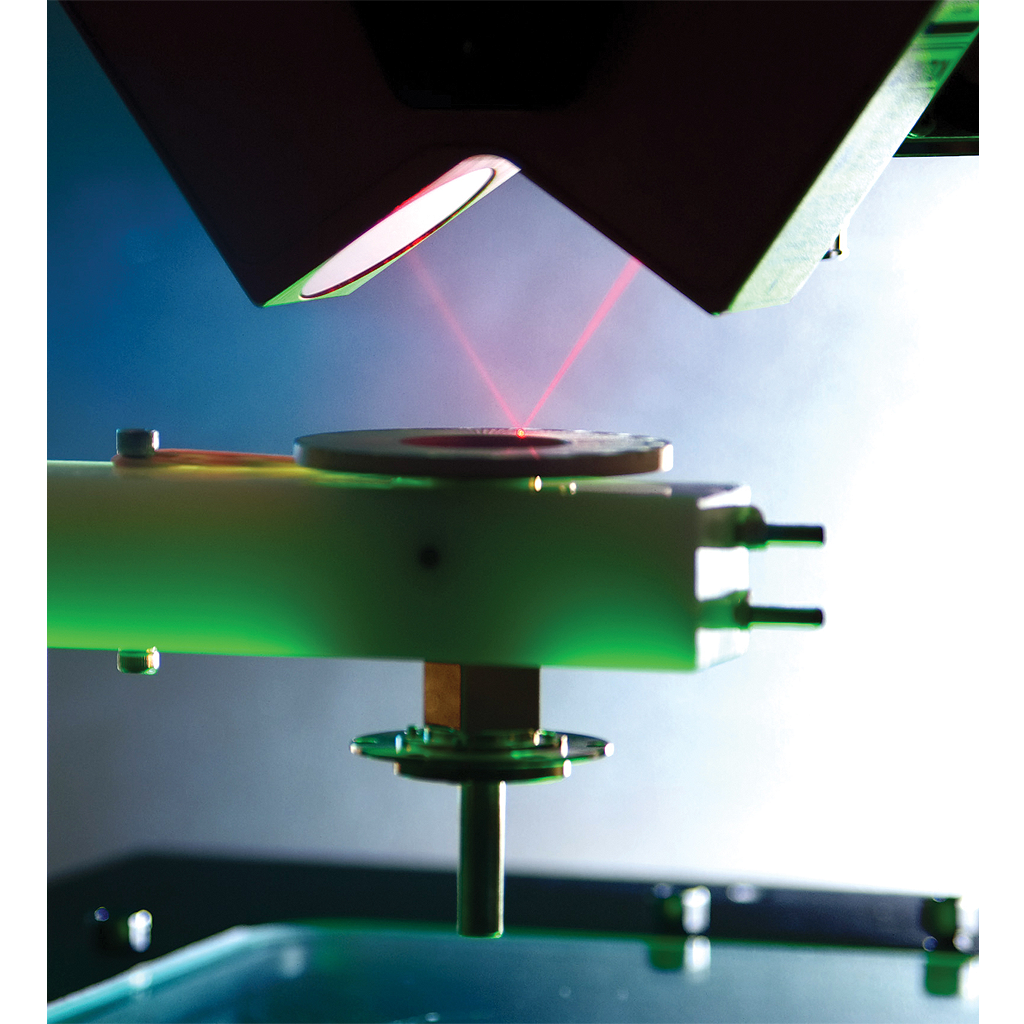

Interferometric range sensor for surface contour measurement. TeleStar Probe offers sub-micron resolution while scanning either specular or diffuse surfaces. Speeds up to 500 points/second. Mounted in automatic deployment mechanism.

| P-20 | P-25-35 | P-25-75 | |

|---|---|---|---|

| Measuring range [mm] | 0,8 | 0,8 | 1,4 |

| Accuracy [μm] | 1 | 1 | 1 |

| Working distance [mm] | 25 | 35 | 70 |

The Tele Star Plus TTL Laser uses a unique interferometric sensing technology that yields a high measurement resolution, accuracy and capability. It is a coaxial with system optics, allowing use over the full range of XY travel.

| Vantage | SP | Fusion | |

|---|---|---|---|

| Measuring range [mm] | 0,8 | 0,8 | 0,8 |

| Accuracy [μm] | 1 | 1 | 3 |

| Working distance [mm] | 71 | 90 | 185 |

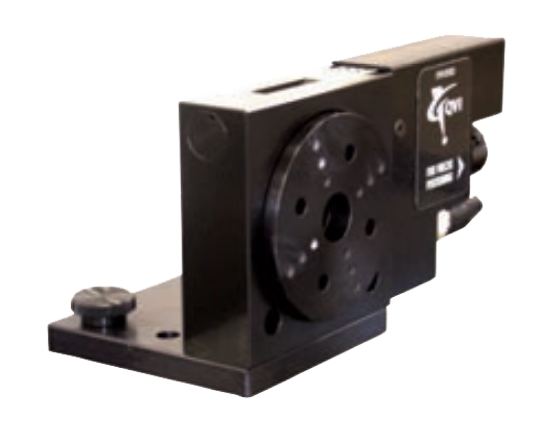

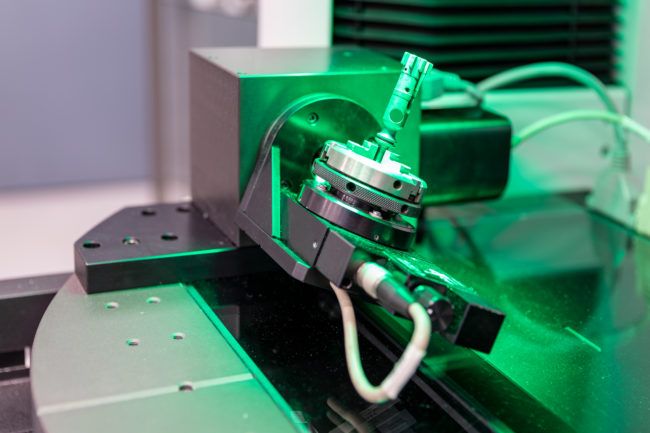

Measuring parts in multiple views under automatic program control. Ideal for screw machine parts and other turned or cylindrical parts. Combine MSR and MTR to provide rotary motions in two perpendicular axes.

| MSR | |

|---|---|

| Resolution (arc seconds) | 16 |

| Accuracy (arc minutes) | ±2 |

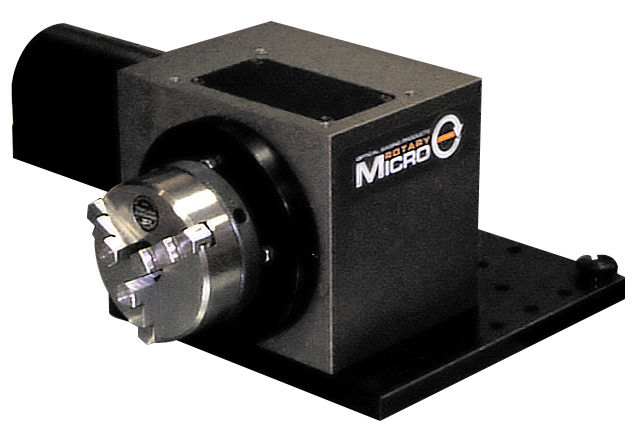

MTR has high-accuracy rotary indexer with twin reader heads. It has double the load capacity of the MSR. Metrology software ZONE3 includes rotary axis calibration routines to locate the rotary in 3D space.

| MTR | |

|---|---|

| Resolution (arc seconds) | 2 |

| Accuracy (arc seconds) | ±5 |

Excellent choice for larger parts or to support a dual rotary combination, allowing a fifth measurement axis. It can carry loads up to 30 kg-cm. HDR is designed for demanding industrial applications.

| HDR | |

|---|---|

| Resolution (arc seconds) | 3,6 |

| Accuracy (arc seconds) | ±5 |

HPR offers high accuracy air-bearing fourth axis measuring. It allow 360 degrees of rotation in less than 8 seconds. Ideal for the most demanding measurements that require the highest precision with an accuracy of ±1 arc second.

| HPR | |

|---|---|

| Resolution (arc seconds) | 0,09 |

| Accuracy (arc seconds) | ±1 |

Two rotary indexers together with their axes perpendicular to one another to add two more axes. Several combinations of rotaries can be configured, depending on the application and the available measurement envelope of the machine.